A few details from history

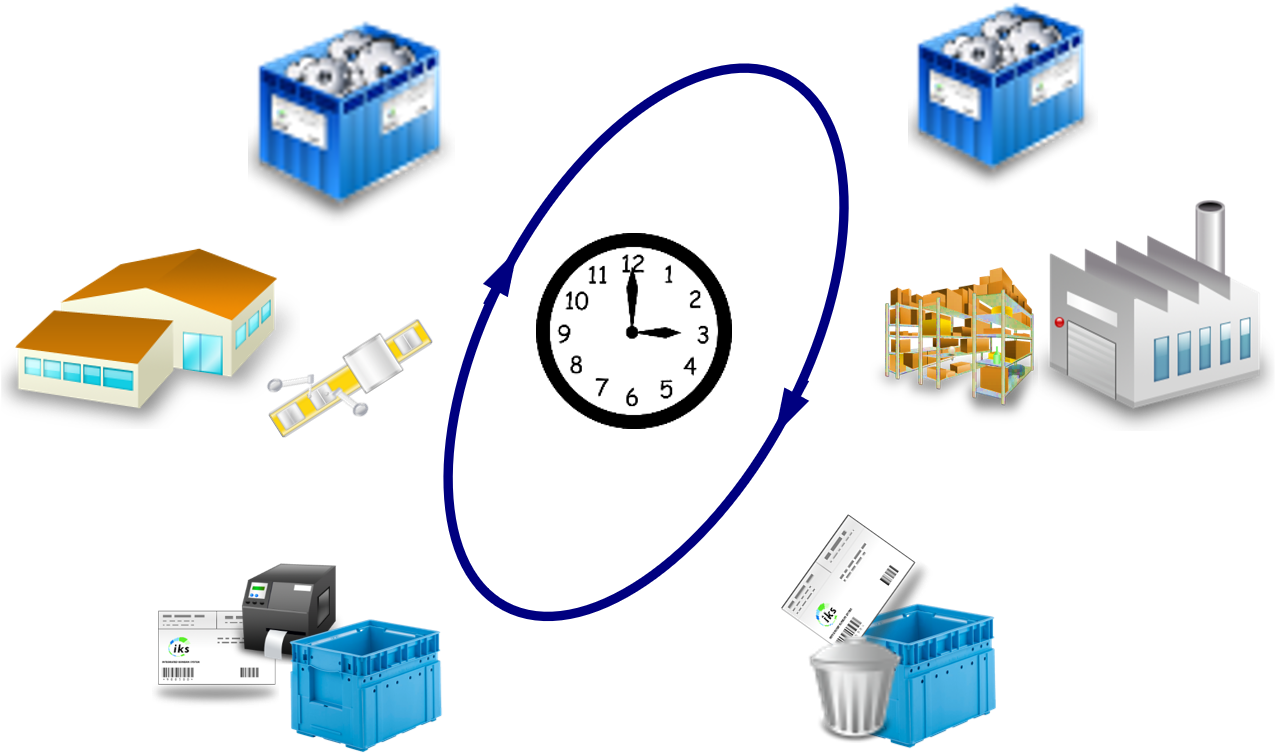

After the 2nd World War when the economy and industry was expanding and the powerful tool KAN-BAN (card-signal) was released. Kanban was developed by Taiichi Ohno in the Japanese Toyota Motor Corporation in 1947. Kanban is advanced visual management driven by consumption and placing the order as Kanban card signal.

看板 = KAN-BAN was born!

Maybe you are now wondering, if it is still valuable after 70 years? The bright future of Kanban is just starting in todays congested global market. For the start I have collected some awesome reasons in the web page “IDEAS”.

Terms

1. 100% quality parts

2. driven by consumption only

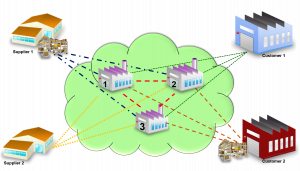

3. fixed relation customer & supplier with locations

4. fixed product, quantity, packaging type, identification type

5. fixed lead times and delivery frequency

6. správná kalkulace kanbanových hladin

7. responsibilities and way of communication

8. support of skilled consultant or very intensive training

- Kanban is able to manage hundreds of items and thousands of kanban cards

- Only highly repetitive items

- Difficult to keep user discipline in manual kanban

- Even the sustainability of the exact number of cards in circulation against the actual stock (many times the cards have been taken away in their self-pockets)

- Kanban requires minimal investment to set up, introduce a qualified team for daily management

- Minimum knowledge of the tensile principle for proper functioning is necessary

- E-kanban modules can automate transaction entry into business systems