IKS SMART FACTORY

Joint solution for users, processes, enterprise systems and SMART technology

How much digitized is your company? Do you have these digital environments interconnected?

Our customers have inspired us in connecting their digital processes as one environment, online and globally anywhere in the world.

No more typing errors, paperwork, time delays or wasted resources.

SMART devices for end-users

Pick-by/to-light

Wireless Smart buttons are intended for quick picking or put-away of material. Buttons helps quick navigation to the right location by high-lighted LED diode and confirm this transaction by pressing the button. Transactions: picking from location, put-away to location, confirm full and confirm empty.

E-LABELs

Pick-by-light electronic shelf labels with up to 7 color displays, 7 color LED light, size 4 – 30 cm, two buttons for actions. Working temperature is between -25°C/ +0°C /+40°C.

E-Ink displays or full colour E-paper, size 33 – 121cm, to be used also for working instructions, maintenance/ service status of the tools or equipment.

Smart Glasses

Simplified navigation to the location and acceleration of material picking and put-away at the final location. On the display of the smart glasses, you will see the necessary information that will make it easier for you to move around the warehouse and make the selection of goods, including the correct quantity, more efficient.

Smart Glove

Smart gloves are simplified for scanning, while the user has free hands and key information directly on the hand. IKS User access is set directly for the glove, which is paired via Bluetooth to a computer. Transaction: scanning according to IKS powers.

SSW sensors

SSW wireless sensors and buttons are used to transmit the request for replenishment and consumption in flow racks or on the open production floor. Location sensor boot for AGV transport transactions, to bring full or take away empty pallet. Transaction: delivered and consumed.

Weight and distance

Wireless smart sensors that weigh the material, measure distances and can also be extended to measure temperature, vibrations, and location tracker. They are intended for materials in original packaging with a demanding consumption countdown. Such as liquids in barrels, coils of sealing or picked in pieces. Information for ordering or refilling can be done during consumption. Transaction: the actual quantity and consumption

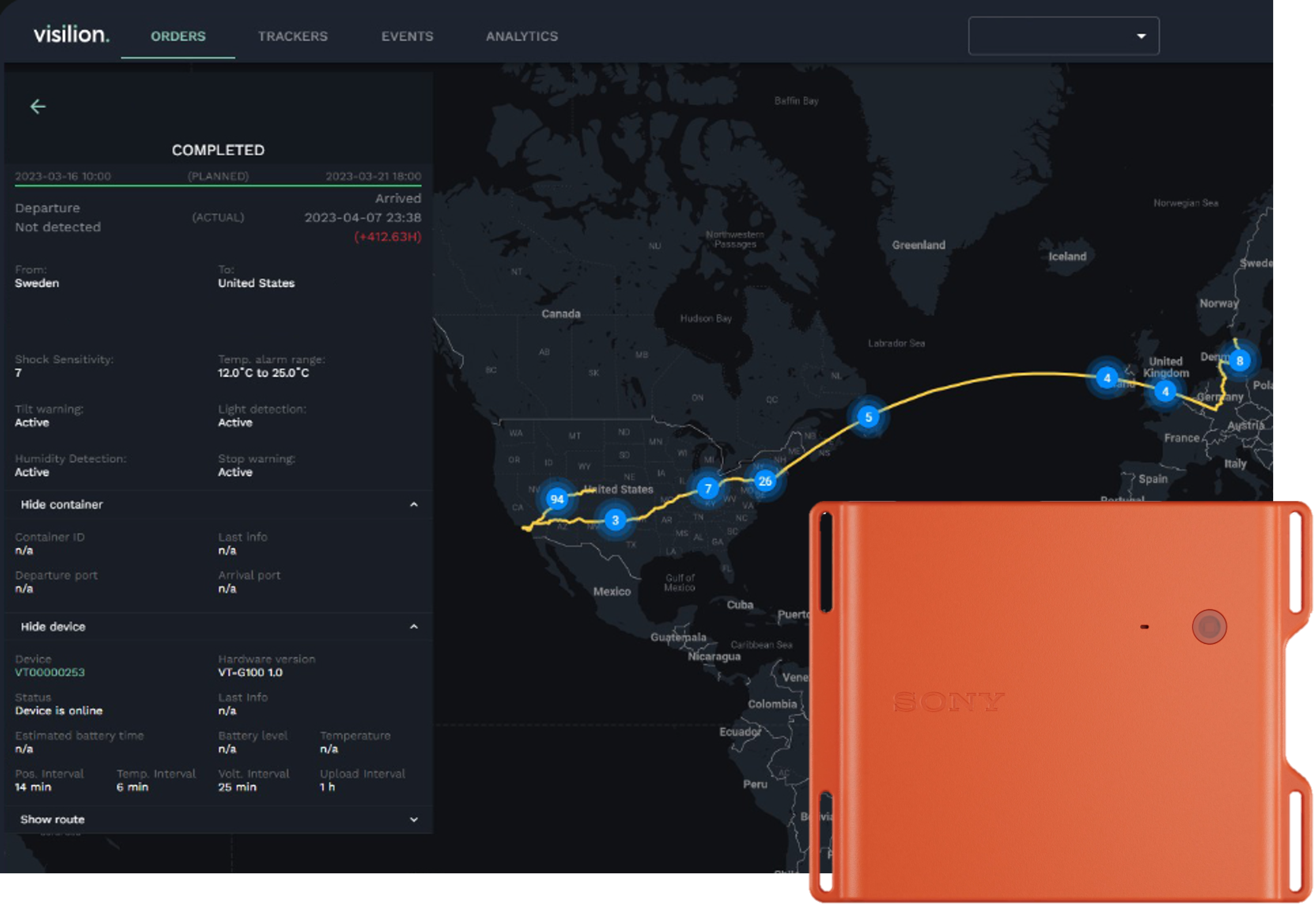

Digitization of transport

Full visibility of IKS shipment, IKS box, or any other assets in GLOBAL motion. This SONY Visilion trackers are state-of-the-art technology to detect location, temperature, humidity, light, shocks, and tilts. (Monitoring climate, un-authorised handlings and opening of the parcel /container). Re-use/ re-turn flows / re-chargeable by USB-C / IP67.

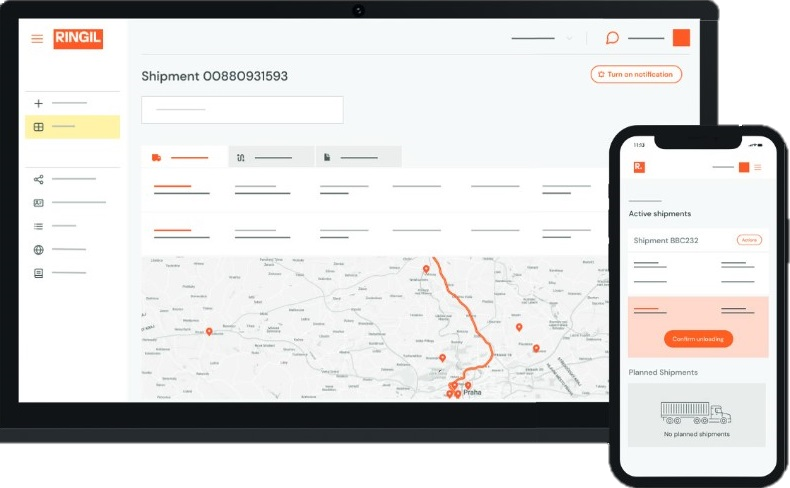

Paperless in real time organized external transports. In the moment when the goods are ready for dispatch the transport request is automatically released and you can monitor transport status in IKS, including GPS tracking. We will help you to optimize transport costs, reduce transport times and enable combinations of routes and processes (deliver exact number of returnable packaging to suppliers and return with the same number of full packages; or periodical milk-run transport from/to several addresses). Be inspired by Ringil and its innovative approach to transport logistics.

Internal AGV transport – one-way road

Fully automated material transfers between robotic workplaces and/or smart locations using “AGV – automatically guided vehicle”. The 4IGV solution currently supports one-way movements from point A to point B, including height defined locations. In IKS, AGVs and “smart transactions” are synchronized online in the form of Shipment orders, and their actual statuses are visualized to the users.

Internal AGV transport – “milk-run” trains

Our goal is fully automated delivery of material to several consecutive locations in the warehouse or production. We can support also semi-automatic milk-run trains, where the operator unloads the boxes and confirms the departure to the next location in the delivery sequence. We already have the milk-run transport process, but we are looking for a good partner to implement this AGV train solution.

Searching for AGV milk-run partner

External kanbans visualisation

Do you have multiple kanban suppliers and you want to simplify the management. IKS Smart Factory can also adopt, standardise and visualize / clone external Kanban tools as well as their complete automated management to the original kanban administrators.

The end of Kanban Excel, Access, and e-mails.

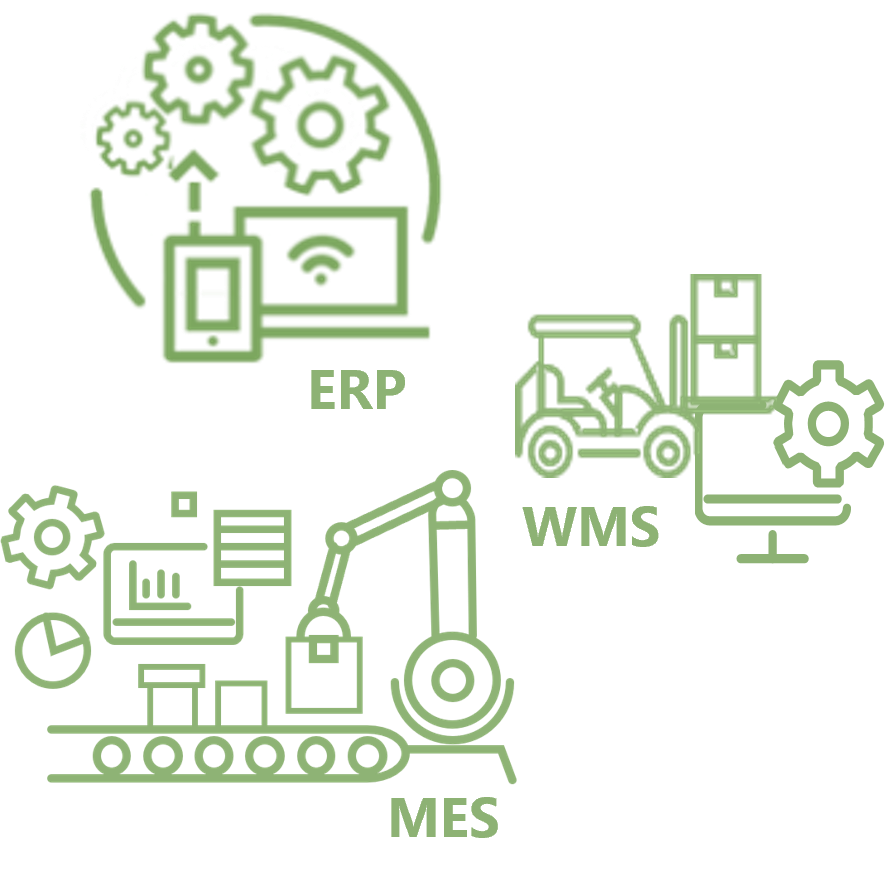

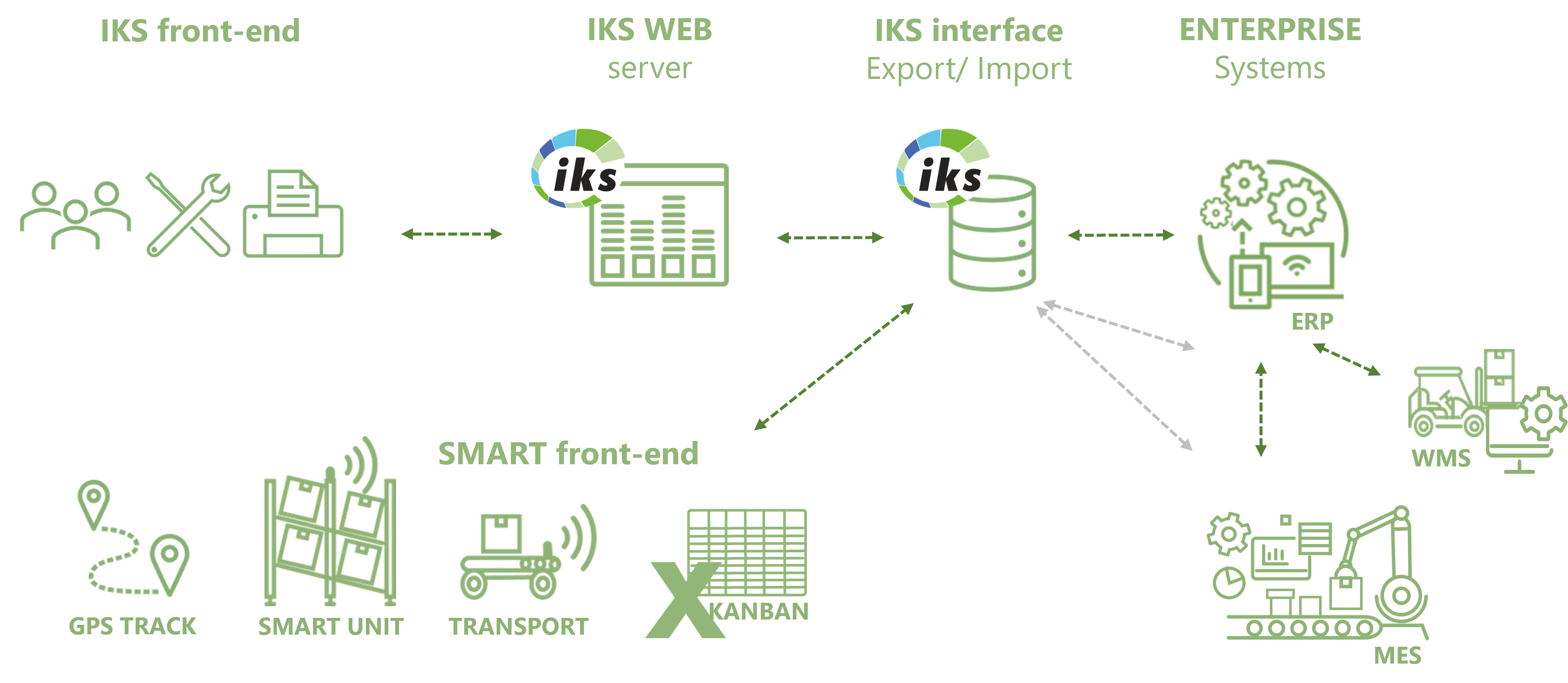

Systems - ERP / MRP / MES / WMS

The integrated Kanban system (IKS) is a professional software system for supporting holistic supply chain processes and the pull principle. IKS does not replace any kind of basic ERP/MRP business systems. But we can connect external/internal key data and transactions of smart devices, B2B, EDI/MES/WMS, which are fully paperless, fast, and correctly recorded in ERP/MRP system.

IKS becomes the only one direct communication bridge into ERP from all external digital technologies, which also makes easy regular upgrades of your ERP system.

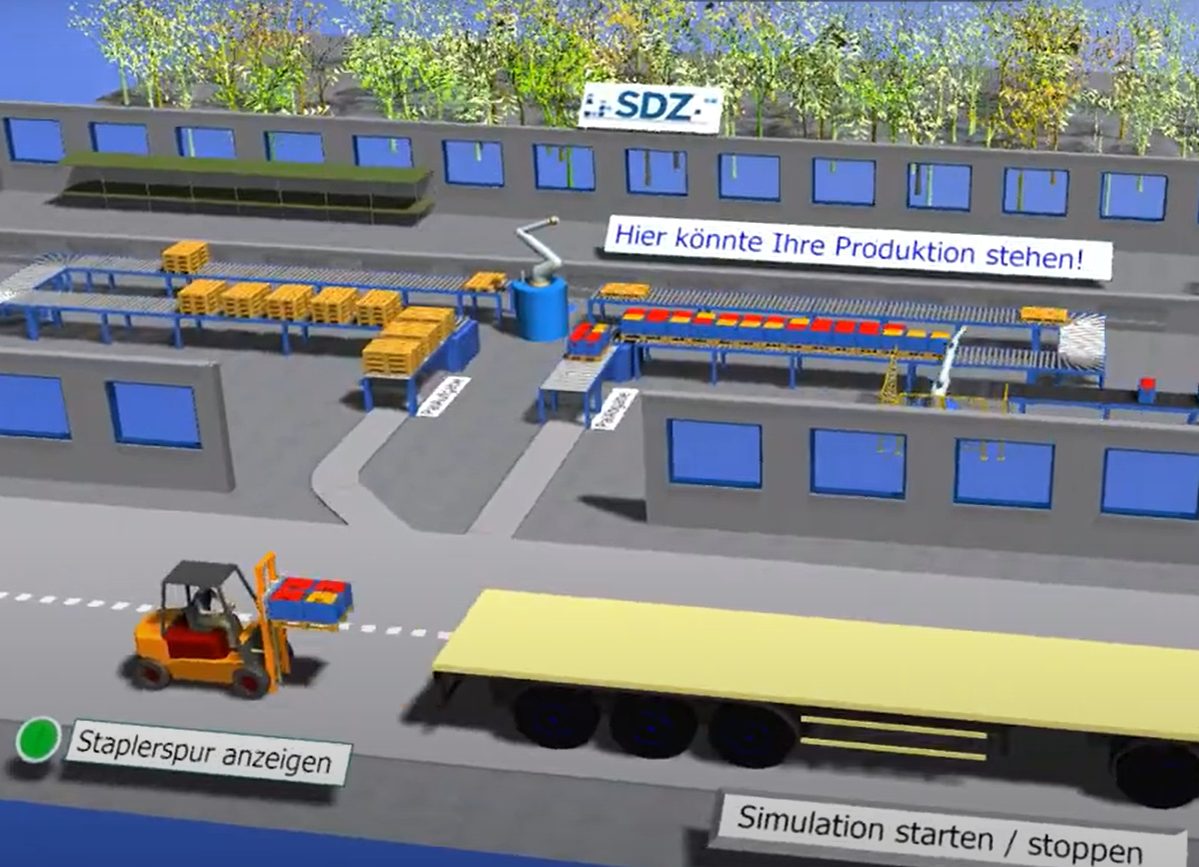

Logistic flow Simulation & Digital Twin

SDZ GmbH and IKS e-kanban a 3D virtual models of are based on IKS Simulator calculation which enables to see future impact on logistic processes results. In IKS Simulator you can compare the current and future process in 3D digital simulated animation. As a high-tech bonus you can integrate online IKS e-kanban data with this 3D logistic animations and mirror the real time situation into your Digital Twin.

Users and processes

In the IKS Smart Factory we have standardised management of all smart technologies in a secured IKS administrator environment. The end-user of logistic process has also great visibility on smart devices performances and functionality.

This standardised environment is significantly minimizing technical support required for managing of digital technologies. Accelerates the detection of potential problems and enables immediate correction.