Basic information on IKS

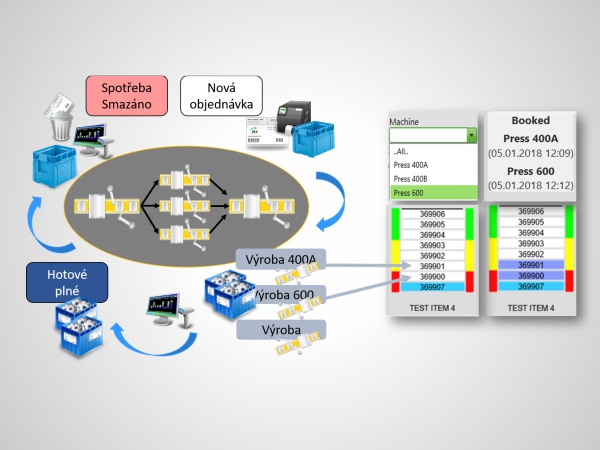

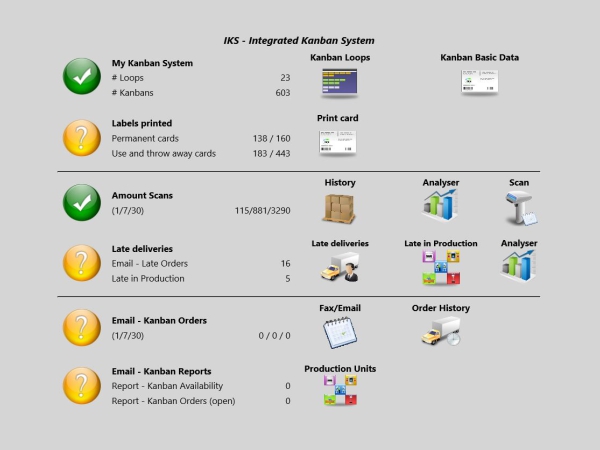

IKS e-kanban utilises are two web-based interfaces; the main user portal ‘IKS WEB’ and the administration portal ‘IKS GF’ intended for the administration of the kanban system.

Users of IKS WEB portal are all internal and external persons who perform daily transactions are users of the IKS WEB portal. A user can see only their assigned kanbans (IKS disallows viewing other’s data). User can use only the assigned IKS functionalities. Each user transaction is marked by a timestamp and the name of the person who performed it.

The IKS Kanban ID is a key piece of information in the entire IKS e-kanban system. This single number contains all the ties and the history of the entire kanban cycle. It can also contain additional information and notes as desired, such as a pallet number, delivery note number, serial/lot information, project ID, start date, and the required delivery date.

The IKS Kanban ID can be used as a single unique life cycle certificate enabling the absolute visibility of each step in the cycle’s history. Or Kanban ID can be used as a permanent marking of a pallet or box that is continuously moving in the loop.

Performing transactions using the IKS Kanban ID

Manual entering (no scanner costs, but may result in typing errors)

Scanning – easy scan of 1D barcode (cheap and error-free solution)

Manual data file load and mass extractions of kanban IDs from a file (fast retrieval of entire truck load)

Import of data files by the server – transactions are carried out in background in the IKS system (requires IT support, mostly used for integration with external systems & PLC robots to nicely visualise analyses in IKS).

Through a Digital data transaction – this is the most expensive option, as it requires additional software and IoT / SSW-System hardware that initiate Kanban ID transaction into the IKS e-kanban system.

Types of IKS transactions

Apart from standard kanban transactions, IKS e-kanban allows users to perform random quality inspections at any state of progress.

Quantity updates for commodities that are handled as units but registered and paid in kilograms (e.g. steel, metals, paper, fibres, or rubber).

IKS e-kanban also offers additional scanning statuses developed for connecting multiple process and transaction visualisations within a single flow.

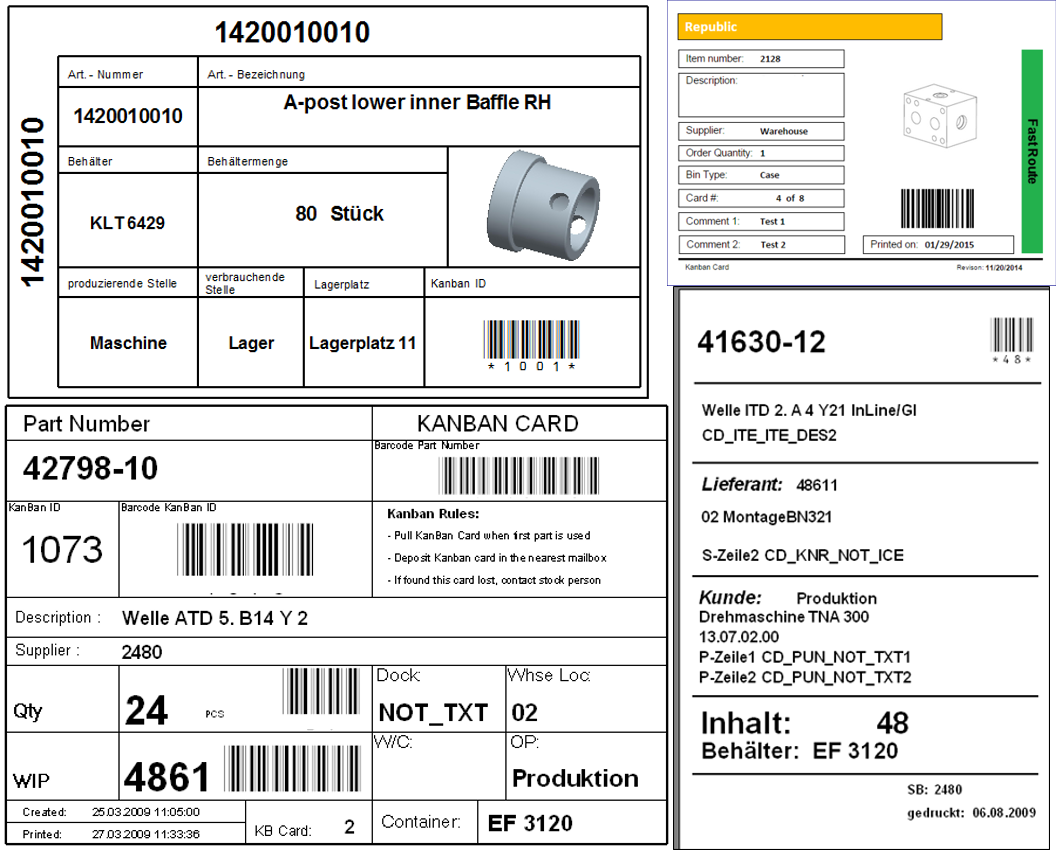

IKS kanban card

Each customer is unique in terms of identification of their materials. When setting up each customer’s IKS environment, a label with the desired layout and size can be defined. Information on the label are mostly: kanban ID, item number and description, quantity, supplier-customer relation, image, and other key information’s to be stored in the IKS system. Size might be based on the existing printer types and the printing label format already used in order to minimise extra costs of printing from IKS.

Printing IKS kanban card

As the entire IKS system is cloud-based, it is possible to print kanban labels any time and from anywhere GLOBALLY. An IKS kanban label can be printed using any available local or network printer. This makes it possible to create labels without any additional costs and without extra movements or users delays.

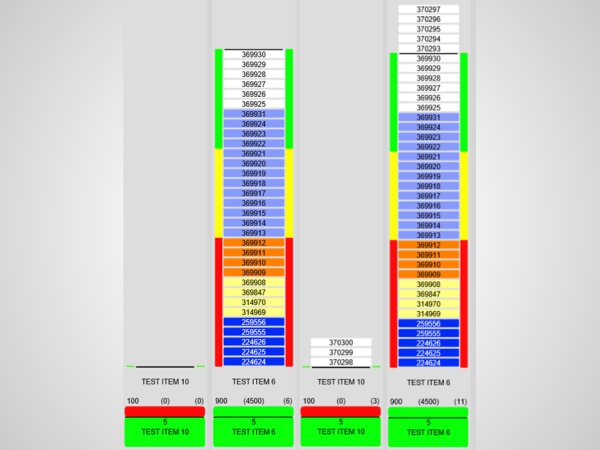

KANBAN BOARD

Provides a complete overview and shows the GLOBAL kanban situation in real time, including all current states and their progress. The kanban situation visualisation shows the availability for the end customer actual situation. The urgencies are always sorted from left (entering view) to right comfort availability, this is another bonus, which allows you to make the right decisions immediately based on real situation.

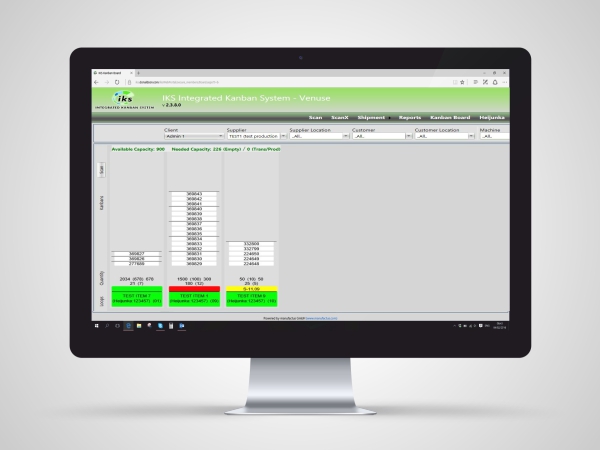

Heijunka Board

Heijunka is tool for optimising production line change-over sequence. We have customers with very complex production processes and technologies. Change-overs to rebuild production line from product to product requires significant time.

An example of this might be a paint shop where it is necessary to group parts of the same colour and paint them in a group as one unit. Due to the necessary pipe cleaning between colours, every change of colour is very time consuming and ineffective when painting small batches. If the colour tones are changed in an optimal sequence, the time needed for such a change-over can be minimised. Therefore the process workflow can be accelerated, including the aggregation of optimal production batche size.

The Heijunka Board display only items with the minimal production volume reached and priorities in sequenced based on optimal change-over times.

This is another great example how to benefit from IKS e-kanban online visualisation by comparing the usual planning standard of fixed shifts or days production plan. Heijunka makes timely respond to customer needs or react on customer urgency as without inefficient change-overs.

Visualisation of machines

Other special features include the multi-sourcing of production equipment to track the resource used to build the product or dual sourcing risk management. In IKS e-kanban, we allow to set up such mutual links between items and available production equipment. Production transaction data then shows the equipment used for the kanban ID completion.

Non-repetitive parts

Originally this special functionality has been created on the basis of customers’ requests, as their items are unstable or affected by seasonality. The objective of this feature is that the Kanban Board should show standardly also the non-repetitive requirements from an ERP system or the customer dispatch schedule.

Furthermore, you can manage your internal/external suppliers as a whole also for low running items. Viewing seasonality requirements, coverage in period of vacations and maintenance. Or items without a standard inventory level as one-time over-kanban or a daily order plan.

This feature can be also used to validate the current planning system as mirroring function. Highlight the process management bottlenecks in IKS online analyses.

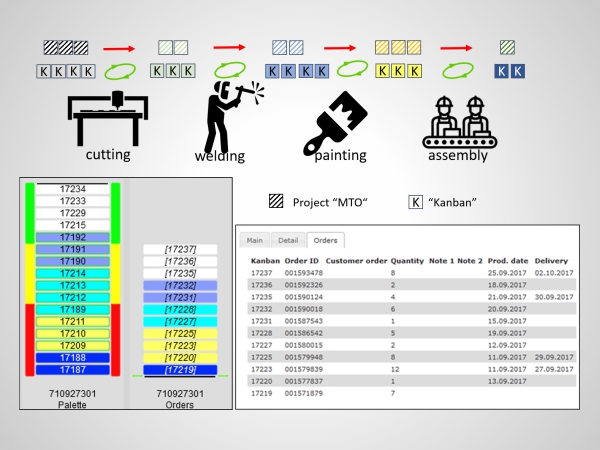

Make to Order

We also have customers who produce custom and drawing-based parts. Our customers asked us to modify the environment of IKS e-kanban in order to support “Project” production or specials “Art-products”. Visualise the workload of on individual workplaces with dynamic priority of each working operation for standard kanban and also project parts.

This visualisation also provides optional key information for decision-making about next production priorities (visualised can be: customer order, production start date or dispatch dates).

The project production feature can also be used as tool of “Project Agile Kanban” to manage globally your projects in the total volume exceeding 100 individual projects running at the same time. The advantage is the possibility to view all resources their capacity to be able to optimise them and flexibly accelerate the releasing and completing of these projects.

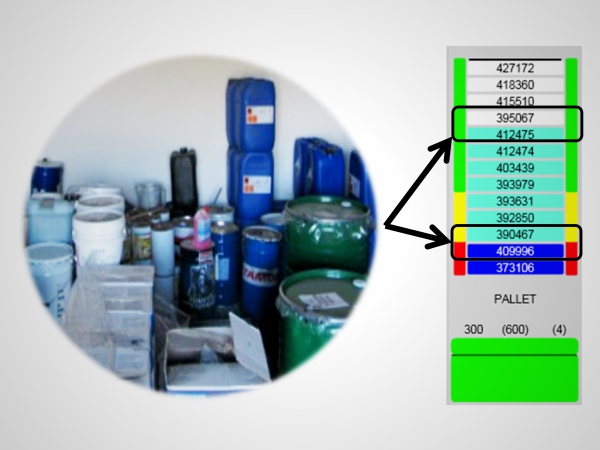

FIFO expiration

If your issues around expired or obsolete materials are also often encountered. Maybe warehouse staff store the items into or take them from the nearest positions, do not rotate stock from higher floors, or from the wall side or from the central positions of block-storing systems? IKS kanban displays each kanban ID from the oldest (bottom) to the newest (up) of each individual processing state.

Is the non-quality production an issue? Is it difficult to track how long ago your material was produced by the supplier and how long it has been waiting for your consumption? When using the holistic kanban flow, you will visualise the complete flow in IKS, from the moment of production by the supplier till the moment of final consumption. Whole life cycle of each kanban ID absolutely transparent.

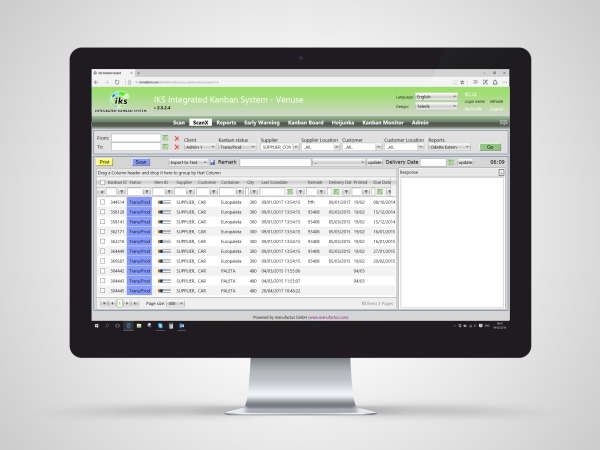

Scanning in batch

This table view menu is mostly used by suppliers when shipping full truck load or by QA departments to confirm inspections results. This function allows the users to easily import and export data files directly from a user screen. In relation to batch (mass)scanning transactions, this page allows the data file upload and forward the set of Kanban ID’s. Another benefit is qty adjustment customized and notes for each individual kanban ID as LOT-serial info, delivery note or FIFO dates.

Reports

With IKS, you do not need to spend time completing delivery or consignment notes. Within a few clicks, you can release user defined reports like kanban delivery notes, summary of item inventory balance per process state, or lists of item availability with urgencies. These reports can be directly printed or exported for further processing in multiple data formats (as xls, pdf, csv, txt).

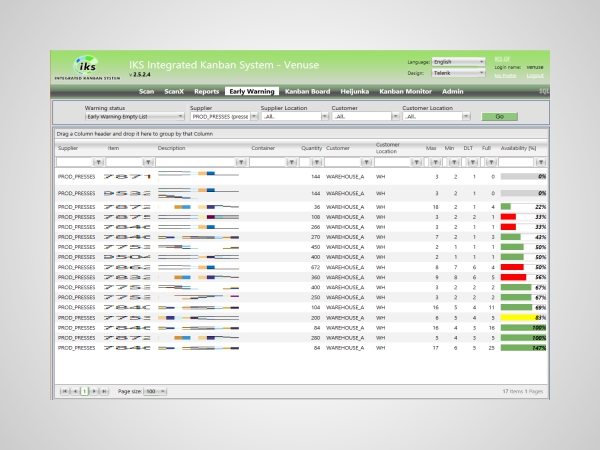

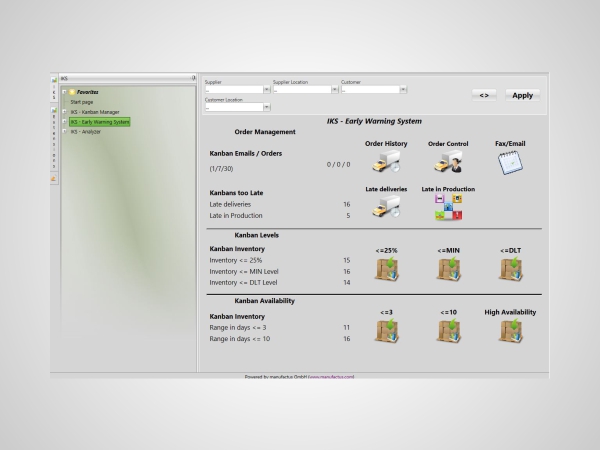

Early warning

In a manual kanban system, it is very difficult to keep control on actual stocks of material, an the problem of insufficient stock usually discovered only when taking out the last item from a package. But by then it is usually too late!

The IKS kanban early warning system allows users to identify kanban loops before they reach critical levels of potential shortage. It helps users to implement timely corrective actions to minimise any shortages of parts or in advance inform customers about risk of reduced availability. You will control your kanban process in real time!

Kanban manager

Is the basic environment of the kanban administration and the brain of the kanban system.

The kanban manager includes this functions:

- setting up all parameters and their relations – kanban loops; setting up process flows; kanban levels, type of calculation; assign Kanban label type and modifications of already existing loops

- a kanban monitor with a table pre-view of the current kanban situation

- Register of revisions history of the loop changes, including details, pending period and the user name who performed it and when

- a history of kanban transactions record at each processing step of every kanban ID, time stamp in seconds and user signature (it’s used as a data source for IKS kanban analyser)

- An integration module to connect external systems, export & import tables and integration table for setting up kanban rules of exported details as part of the IKS kanban system

- Fax/email – setting up of rules and frequency of fax or e-mail messages

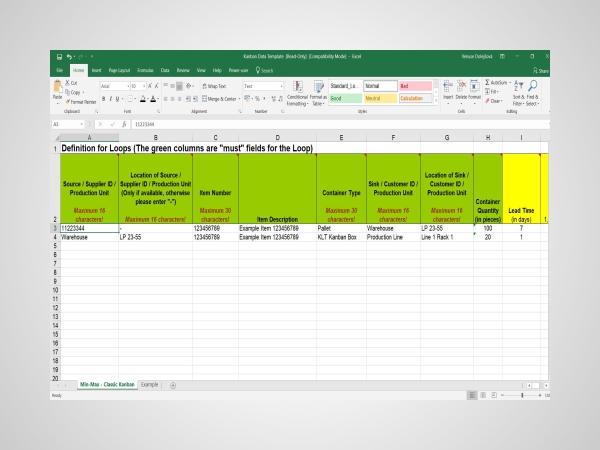

Initial set-up

The initial IKS e-kanban loops set-up can be assisted by the data loading tool that reads an Excel template containing all required information. In few clicks and within a few seconds your IKS kanban will be ready to be used. This tool can also be used in the future when you expand your system by including new suppliers or customers, production processes and new items.

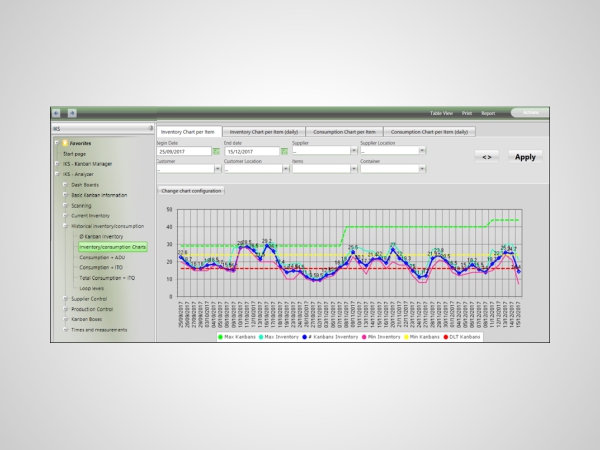

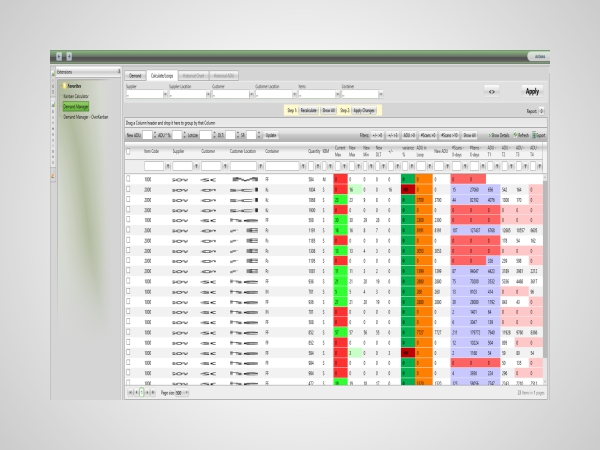

Re-Calculating

Recalculating of your kanban system can be very time-consuming task. In IKS the recalculation and review of thousands of items can be done within a few minutes.

This tool is designed for a fast calculation of requirements and validate with historical records in IKS, forecasted demand in ERP, or both data sources with pre-defined rule. Forecast file (xls, csv, txt) can be loaded manually or automatically. Available historical charts can support fast and correct decisions. The final update of loop parameters can be performed in bulk, or by a individual selection of specific kanban loop.

Early warning

Also in the kanban admin environment we offer an advanced version of early warning system, as well as multiple options of how to view the actual kanban situation.

The early warning system high-light kanban loops with risk of availability shortage. This helps users to take immediate actions and minimise the shortage impact on customers. You will always have your kanban situation under control and parts for all your internal and external customers will be at 100% service level!

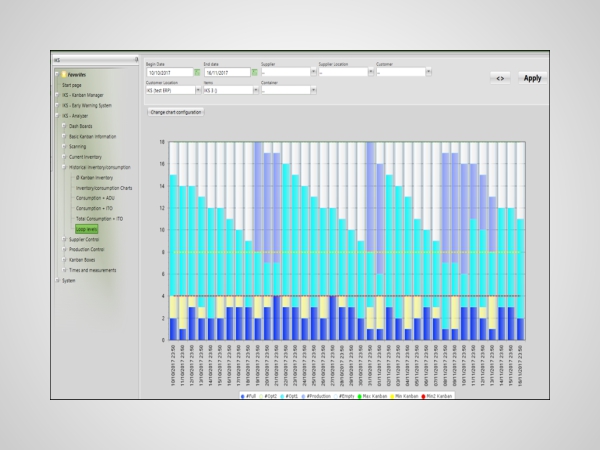

Analyses and charts

They are a very important tool for monitoring of key performance indicators and data source of continuous improvements. You will gain more than 120 pre-defined reports with very flexible filers to view specific data and time period.

Reports can be directly printed or downloaded in multiple formats. All data displayed on charts can be pulled out also as table in to Excel file. Analyses results are used for fast improvements and optimisation of the kanban system (stock levels, consumption, lead times, delivery period, etc.)